Mission critical

dam services

For the mining & gas industries

EVAPORATION MANAGEMENT | SEEPAGE REMEDIATION | SEALING SOLUTIONS

contact us

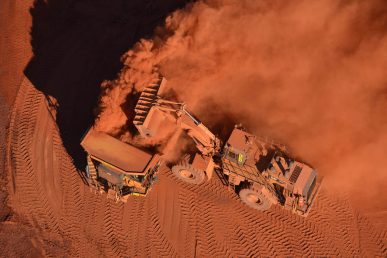

Gina Rinehart’s $10 billion Roy Hill mine in Karratha WA is Australia’s largest iron ore mine – and Ms Rinehart is Australia’s richest person.

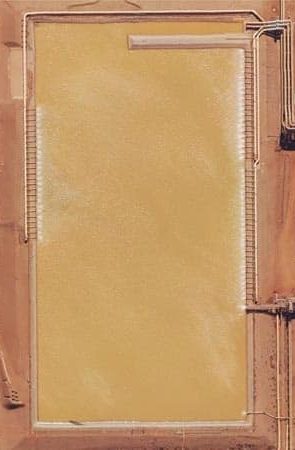

Roy Hill had a problem with the dam liner in their 100 megalitre processing dam.

We introduced them to a clean, green, organic solution – at a cost of just 20% of their $10 million repair budget.

This was our solution

ROY HILL DAM LINER REPLACEMENT

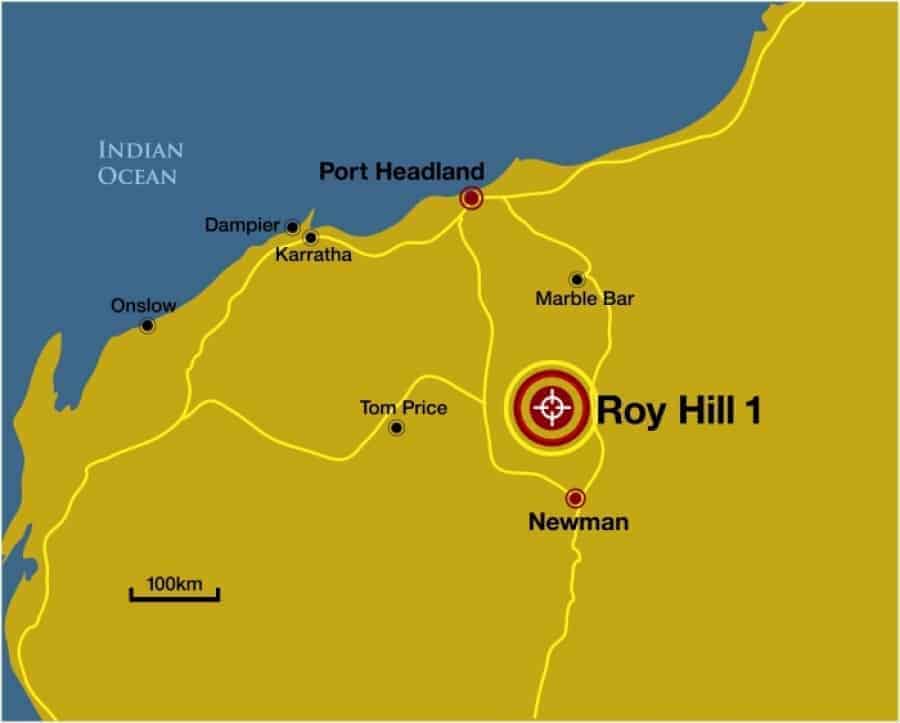

Karratha | Western Australia

ROY HILL

Australia’s Largest Iron Ore Mine

Highway 138 is an isolated rural road linking Roy Hill to the WA coast and the transport hub of Port Hedland

THE PROBLEM

The accelerated ageing of the liner in the 100mgl processing dam.

The company was looking for a long-term strategy to replace it.

Budget: $10m

stakeholders

Gina Rinehart’s Hancock Prospecting is the majority stakeholder in the $10 billion project with a 70% interest.

The remaining 30% stake is held by a consortium comprising POSCO (12.5%), Marubeni (15%), and China Steel Corporation (2.5%).

mission critical

Un-interrupted operations are Roy Hill’s number one priority

The worst thing water management can cause is a delay in mining operations.

the challenge

The challenge is to propose a solution that will ensure the dam contains water.

The solution shouldn’t require extensive plant downtime, or the construction of a new dam.

The solution is anticipated to be one of the following:

- A permanent solution that prevents the dam from leaking for the remaining life of the mine (20 years)

- An interim solution which delays the requirement for relining the dam or constructing a new dam

- A solution to “patch” cracks and/or tears in the liner

WHAT IS THE SOLUTION WE PROPOSED?

- Pull the liner out

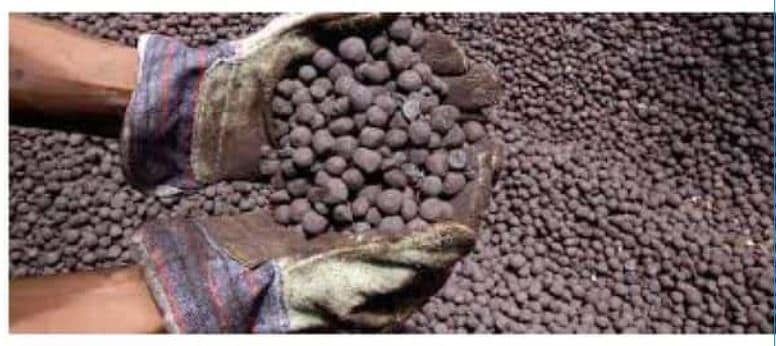

- Implement a dry blanket of Bentonite

AN INTRODUCTION TO BENTONITE

Bentonite is sometimes called the ‘mineral of a thousand users’

It is charactersied by properties such as its ability to swell in water, to act as a ‘natural glue’ or ‘bond’, special rheological properties when added to water (e.g. thixotropy), high surface area and exchangeable cations

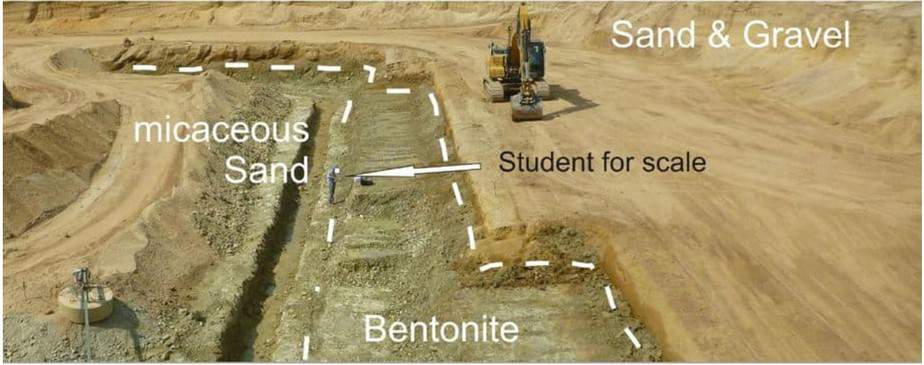

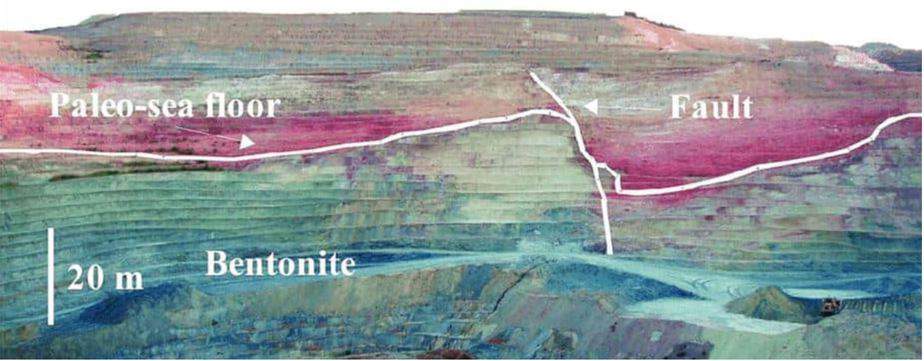

THE ORIGIN OF BENTONITE

Bentonite occurs in rocks that were deposited in the Ordovician to Neogene periods (about 488.3 to 2.6 million years ago). It is formed by decomposition of volcanic ash or tuff, or sometimes from other igneous of sedimentary rocks. Andesitic to rhyolitic volcanic rocks are the most common primary sources.

THE NATURE OF BENTONITE

Bentonite varieties are distinguished of the basis of their principal exchangeable cation, hence sodium, calcium, magnesium- (saponite), potassium- (meta-bentonite) and lithium- (hectorite) bentonite

Bentonite unite are commonly laterally extensive starts within volcanogenic sedimentary sequences.

They may vary in thickness from a few centimeters to tens of metres, and range from Permian to Pleistocene in age.

This is because smectite clays are unstable at higher pressures, and bentonite is increasingly transformed into mixed illite-smectite with increasing depth of burial.

THE HISTORY OF BENTONITE

Bentonite has been used for therapeutic cosmetic purposes since approximately 2500BC.

It has been known as a healing clay for centuries among indigenous people from Australia, the Andes and Central Africa.

The first recorded use can traced back to ancient Mesopotamia.

It is totally natural and well known for its detoxification properties.

People use the clay to detoxify the body, improve digestions and improve skin tone.

In Iran, the clay is used as a hair cleanser and softener.

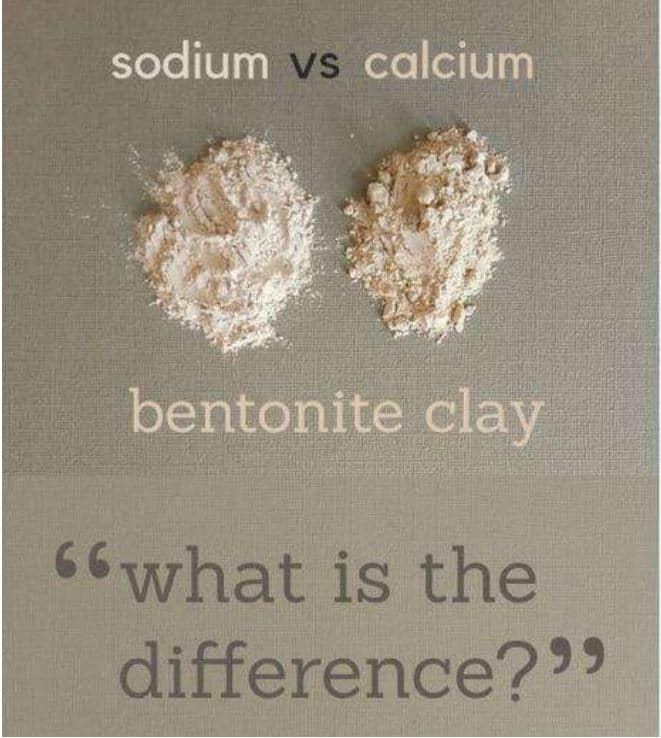

TYPES OF BENTONITE

There are two main types of bentonite

1. High Swelling (Sodium)

2. Low Swelling (Calcium)

SODIUM BENTONITE

The property of high swelling makes sodium bentonite an excellent sealant, since it provides a self-sealing, low permeability barrier.

Sodium bentonite absorb large quanitites of water, swelling to many times their orginal volume, and give rise to permananent suspensions of gellike masses, which provides colloidal and wall-building properties.

Sodium bentonite is used to seal dams; in boding foundry sands, asbestos, and mineral wool; as drilling muds; in cements and concretes, ceramics, emulsions, insecticides, soaps, pharmacuticals, and paints.

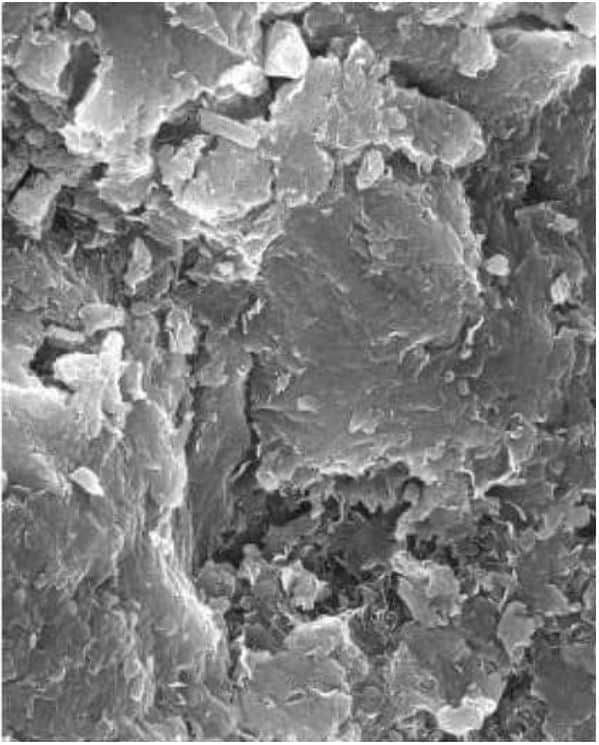

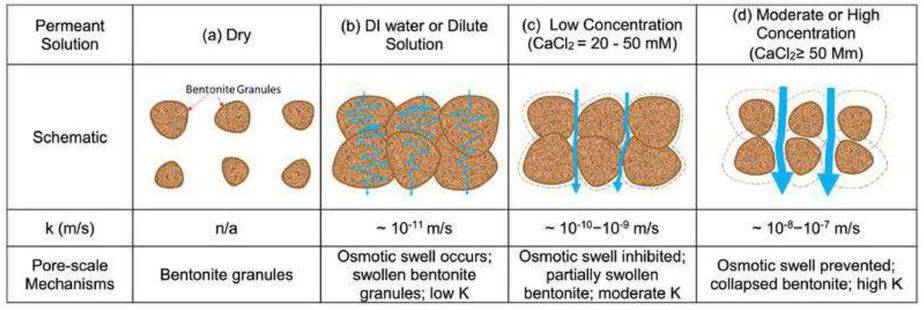

THE SWELLING MECHANISM OF BENTONITE

The swelling mechanism of bentonite results from the unique microstructure and its net negative charge.

The swelling effect results from additional embedding of water molecules.

With the increase of the water content, the thickness of the water film increases.

The swelling in Bentonite is a strong hydraulic mechanic checmical (HMC) coupling phenomenon.

THE APPLICATION OF BENTONITE

Civil engineering grade bentonite has been used for many years in diaphragm wall construction, tunneling and dam sealing-where the soils are highly permeable and impermeable barrier in required.

Bentonite clay expands to several times its dry volume on writing and swollen mass fills the voids and blinds the soil particles to create and impermeable seal, thereby reducing the rate of water movement through porous soil.

Applied as a blanket or mixed with the local clay, Is ideally suited to large-scale water storage sealing, and it provides and economical method of creating high performance seepage barriers.

It has a very low permeability (fluid loss) which becomes even more impermeable under increased head pressure.

If you have questions about sealing dams with Bentonite, just ask us a question

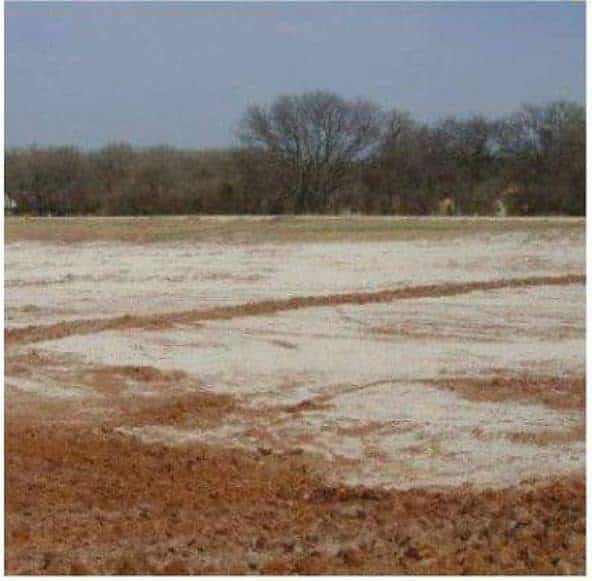

DRY BLANKET APPLICATION

In a dry blanket application, bentonite is spread on the soil surface then mixed thoroughly into the top 600mm of soil using LGP dozer deep ripping, followed by wetting down and then final compaction of the moist bentonite-soil mixture.

As a dry blanket, bentonite is spread uniformly over the soil surface to form a continuous sealing layer that is mixed with protective layer of non-erodible soil.

Bentonite can be dried & re-swelled an infinite number of times.

SOIL BLENDING

Basic soil suitability criteria for a Bentonite dry blanket are:

- 20%-40% clay content

- Uniform particle size distribution i.e. well graded soil

- Slight to moderate linear shrinkage

- Kaolinite-dominant clay mineralogy

A 600mm thick compacted soil blanket with a minimum 92% of mazimum dry density is recommended to reduce seepage to a maximum of 2mm per day.

Such a blanket occupies significant volume in a dam, and prior to placement, excavation to compensate for the loss of capacity will be an extra cost.

COMPACTION

To achieve optimum compaction, soil moisture content should be at near to the optimum, 36-20% for highly plastic clays, and the minimum soil layer thickness should be 600mm.

Compaction is best done with a pad roller of adequate weight and power – and at least four passes should be made by the compacting equipment.

REFILLING THE DAM

Allow inflow to enter the lined dam via a stable inlet (generally require an embankment or slit trap across the open front of the dam to direct inflow to the inlet structure).

Fill the dam slowly (30cm a day) to allow for proper wetting of the Bentonite, and gradually increase load on the embankment.

BLOG UPDATE

Did you know that dam construction failures due to regulatory non-compliance have led to catastrophic ...

When it comes to commercial construction projects, dam building is one of the most crucial ...

Dams play a vital role in managing water resources, supporting irrigation, and generating power. They ...

Natural swimming pools, praised for their eco-friendliness and aesthetic appeal, face challenges like maintenance complexity, ...

Natural swimming pools, praised for their eco-friendliness and aesthetic appeal, face challenges like maintenance complexity, ...

Australia grapples with recurrent droughts, impacting states differently due to factors like climate patterns, rainfall, ...

The article discusses how climate change exacerbates heatwaves, droughts, wildfires, and floods. Rising temperatures, altered ...

New research from the University of Queensland reveals that a significant portion of the world's ...