Why Is Evaporation Management in Dams Important?

The importance of effective evaporation management is evident. Did you know that there are more than 8,000,000 megalitres (ML) of water stored in over two million dams across Australia? Unfortunately, according to recent data, up to 40% of this water is lost due to evaporation.

In our previous article related to Evaporation management we explained some basics on the subject and now want to dig deeper so that you know how to save every drop of fresh water.

From ineffective design to poor dam maintenance, there are many factors that can lead to high rates of dam evaporation. It’s not a secret that the effect of climate change on water availability is also detrimental; extreme weather, reduced precipitation, and prevailing winds, global and local climate systems are changing. Freshwater has already become a sacred resource across the globe and Australia, in particular.

You don’t have to be a dam owner or a hydraulic engineer to know that dams play a crucial role in agriculture, irrigation, and water consumption around the world, with evaporation management playing a crucial role in dam maintenance.

Poor evaporation management can lead to water shortage, which can reduce crop, animal, and human health. Have you ever asked yourself where your tap water comes from? Water shortage can also affect businesses and economies worldwide. The social and aesthetic impact of evaporation should be considered as well. Let’s admit it – an empty dam is of low aesthetic value!

It’s not only about human health and productivity, though. Poor evaporation management in dams can impact vegetation and wildlife. Evaporation can lead to high salinity which can kill aquatic species. Poor evaporation management also leads to low levels of oxygen and increases toxicity, which can be extremely harmful. Fish suffocation, for instance, is one of the devastating effects of high evaporation rates in dams.

Factors that Affect Evaporation Management in Dams

Evaporation is a natural process that occurs every single day, an important step of the Earth’s water cycle. Factors, such as temperature, surface area, humidity, wind speed, and flow rate of air affect evaporation in dams. Naturally, the more surface exposed, the higher the evaporation rates. High temperatures lead to high water molecule energy, which means that water is more likely to break its liquid bond and vaporise.

When it comes to humidity and evaporation, we should mention that high humidity means low evaporation. High relative humidity means there’s a high saturation of vaporised water particles and little space in the air for more water to vaporise.

High winds, on the other hand, lead to fast evaporation. Wind transports vapour, which prevents the air above the dam from reaching 100% humidity and the opportunity for water molecules to collide and re-enter the dam.

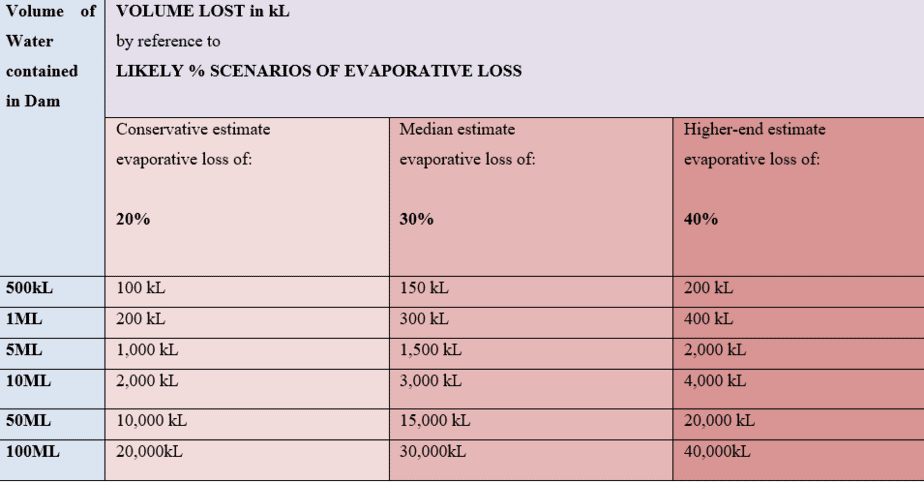

Though it’s hard to measure and stop evaporation, there are many other factors that have to be taken into account, including depth, atmospheric pressure, fugacity, and wave action. Based on recent research data, dam owners and experts can explore various scenarios that can help them to calculate how much water their dam is losing:

Factors that Affect Evaporation Management in Australia

While there are numerous factors that affect evaporation management practices across the globe, it’s not a secret that Australia, considered the driest inhabited continent, has some unique challenges. Alarmingly, the UNSW Water Research Centre in collaboration with the Commonwealth Scientific and Industrial Research Organisation (CSIRO) analysed 12 years of pan evaporation data and concluded that previously decreasing pan evaporation trends are now increasing due to extremely high air temperatures. In Australia, in particular, the impact of the Millennium Drought is one of the most devastating causative factors.

Wind and rain patterns are also changing, affecting particularly the subtropics. Graphic data clearly represents record rainfall deficiencies, with 2019 being the driest year in Australia on record; at 277.6 mm or 40% below average. Alarmingly, these trends are not going to disappear. To provide an example, experts at the Australian Government Department of Climate Change and Energy Efficiency predict a decrease of about 2% by 2030 and 5% by 2050. On top of that, 2019 was the hottest year in Australia, with the annual national mean temperature 1.52 °C above average.

It’s not only rainfall deficiencies and high temperatures but poor water quality. The impact of bushfires is detrimental as fires can lead to a wide range of damages, erosion, and turbidity (high volumes of sediment). Chemical reactions by fire can release toxicants; furthermore, rainfall after a fire can wash these contaminants into dams and waterways with substantial implications for agriculture and human safety. Combined with increased contaminant loading, high water temperatures can trigger a greater breakdown of organic matter by bacteria and deplete oxygen levels in the water. Not only that, but fires generate vast amounts of carbon dioxide, which is one of the greenhouse gases responsible for global climate change.

How to Improve Evaporation Management in Dams

As we can see, proper evaporation management is essential to improve water quality and environmental health. From improved dam design to windbreaks, there are different methods that dam owners can employ to improve their evaporation management practices.

Additionally, various evaporation management techniques exist that can reduce evaporation, sometimes by 90%. For instance, water loss from evaporation can be managed using either natural or manufactured tools. Note that each method has its pros and cons, so selecting an evaporation reduction method should be specific to an owner’s requirements and their unique dam structure, purpose, and environment.

Owners can consider different physical and chemical means, with underground storage tanks being among the most effective methods to reduce evaporation management concerns:

| SYSTEM OF EMT The evaporation reduction % are based on trial data and individual product claims. Please note different products within a system and different dam specifications vary efficiency | SYSTEM DESCRIPTION | SURFACE AREA APPLICABILITY |

| SUSPENDED COVERS Evaporation Reduction of 50% to 80% | Generally suspended UV rated shade above the water surface. Usually secured with using a cable in a web-like structure, although shade cloths attached to modular rafts are a variance. | Up to 10 hectares |

| FLOATING CONTINUOUS COVER Evaporation Reduction of 85% to 95% | An impermeable sheet-like cover placed atop of the water, usually secured by a tensioning system. Commonly made of polyethylene plastic containing buoyancy cells (like bubble wrap). The polyethylene used can be recycled and is environmentally safe. | Up to 4 hectares |

| BLADDERS In terms of evaporation control, it simply acts as a Floating Continuous Cover, thus Evaporation Reduction of 85%vto 95% | Generally made from polyethylene and provide an impermeable lining both above and below the water body, thus seepage reduction also assisted. The principal is similar to that of a wine cask. Rain does not have any way of entering the bladder. | Small dams only |

| CHEMICAL COVER (Monolayers & Polymers) Evaporation Reduction of 5% to 30% (monolayer) and up to 50% (polymer) | “Self-Spreading” thin invisible film of chemical compound cover. These create a physical barrier with pores smaller than H2O, thus creating a chemical shield over the water. May be applied by hand. The term “monolayer” seems to have been adopted when referring to any Chemical Cover, however a monolayer is just one type of Chemical Cover. Chemical “monolayer” compounds ~2 millionths of a mm thick and requires reapplication every 48 to 72 hours. Polymer compounds greater than ~2 millionths of a mm thick and therefore not a “true monolayer”, these require reapplication every 3 weeks, claiming a higher efficiency than monolayers. | Unlimited |

| FLOATING MODULAR COVER Evaporation Reduction of 80% to 99% | Discontinuous individual modular structures of any shape, which are generally 100mm to 230mm in diameter (with some up to 1181mm) and, when used together, form a flexible and protective cover. They are not usually attached to each other. You may be familiar with one type – the floating shade ball. Included in this category would also be homemade fixes such as tyres filled with foam or even floating plastic bottles. Naturally, homemade fixes require careful analysis of possible environmental consequences. Big Ditch is the first company globally to be trialing Pumice is 100% organic pumice for evaporation management. Pumice has no toxic effects on fish life and the irregular shape allows oxygen and rainfall into the water body. Advantages are significant wind stability and excellent buoyancy with the tiny holes encouraging the growth of water cleaning microbes. | Unlimited |

| FLOATING MODULAR COVER II: UNIQUE CATEGORY: FLOATING SOLAR PHOTOVOLTAIC SYSTEMS (FSPVS) More research required with small scale trial indications showing Evaporation Reduction may be approximately 30% (Melvin, 2015) | Floating solar arrays capable of power generation of approximately 10w – 130w per meter square. In use for a little over a decade. Research and data on effectiveness as an evaporation mitigation tool is limited as, to date, the primary focus has been power generation in the context of land shortages. Cost is high – well over 4 to 5 times more than Floating Modular Covers. FSPVS is not specifically designed for cooling thus its heat retention / higher temperature impacts effectiveness for evaporation. | Known to be constructed on sites up to 80 hectares |

BUBBLE PLUME (Artificial Destratification) More research required, with indications of an annual overall annual Evaporation Reduction of approximately 6%. Effectiveness highly seasonal. | A bubble plume is injected in the dense, deeper cold dam water and rises through into the less dense, warmer surface layer of water. Mixing the water creates a cooler, denser surface water and reduced evaporation. The bubble injecting diffusers are placed at a specific height above the bottom of the reservoir to prevent the disruption of the bed sediments. This system has been installed in reservoirs around the world primarily for the water quality benefits – as with FSPVS, there is limited research into evaporation mitigation effectiveness. A recent Griffith University study undertook modelling of different destratification conditions and two different depths: 6.5 and 13.5 metres. Results showed that destratification can reduce surface temperature and evaporation from both shallow and deep waters, however higher effectiveness is expected in deeper water but the reduction in surface water temperature and evaporation will not be significant during hot weather periods. | Suitable for very large dams |

| BIOLOGICAL Impact on evaporation reduction is not yet well researched and is a little more complex as plants themselves uptake water – 10% reported in Thailand (duckweed) (NSW DPI, 2008) PALM FROND: Small scale trial indicated 63% evaporation reduction Al-Hassoun et al. (2011) | FLOATING PLANTS Free Floating Native free-floating plants include Azolla species and duckweeds including Lemna species, Wolffia species and Spirodela species. Submersed Floating ie. Waterlilies, watershield, and spatterdock. PALM FRONDS Recycled palm fronds used as a Floating Cover (as opposed to when they are used as a Suspended Cover) have been trialled on a small scale. | Free Floating– unlimited although optimal is 40-60% coverage of a water body. Submerged Floating – shallow waters but may grow in up to 3M. Limited by depths to which roots can attach to bottom. Palm Fronds – limited by practical considerations for collection and quantities required for larger dams |

Evaporation Management in Dams: In a Nutshell

Though evaporation is a normal process, high evaporation rates in dam management can be detrimental and affect both human and environmental health. While controlling for meteorological factors, such as increasing temperatures, drought, and greenhouse gases is almost impossible, dam owners should consider different evaporation management methods.

From improved design principles to suspended floating covers to floating plants, there are different methods to reduce evaporation in dams, with underground storage tanks being among the most effective solutions. Interestingly, pumice is another innovative material that can be employed in evaporation management practices.

Evaporation management is a challenging aspect of dam maintenance, especially in Australia where climate change, unpredictable rainfall, and drought make water a scared resource. We at Big Ditch are here to give you a sip of freshwater! Simply contact us for more information and evaporation control advice.