Does your dam have the bad compaction blues?

Dam wall compaction issues

Do you have a dam that refuses to hold water – even though the person who built it rolled and compacted the wall for days?

Your problem might be ‘pancake’ compaction – or what is technically known as horizontal linear compaction.

It’s a compaction technique that should never be used

Does your dam look like this?

This dam located in Razorback NSW is on a multi million dollar property, but has never held water since it was constructed.

Dams that can be seen from the property residence should add $3 of value for every $1 of construction cost.

But the net effect here is that this dam is dragging down the property value.

So, what’s the problem?

Problem identification

The current dam wall is an old style trapazoidal design that was popular in the 1970’s, with a steep ingress of 45 degrees and a crest to base ratio of 1:3

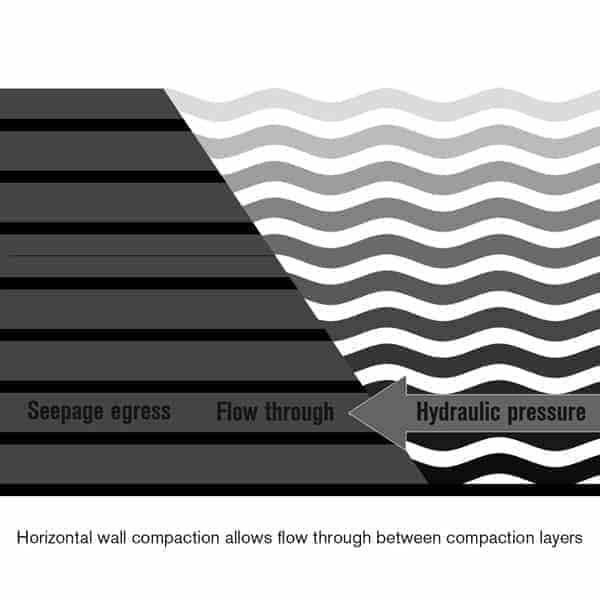

Pancake compaction

The current inability of the dam wall to hold water is due to two design flaws:

1.Use of dispersive red clays in construction

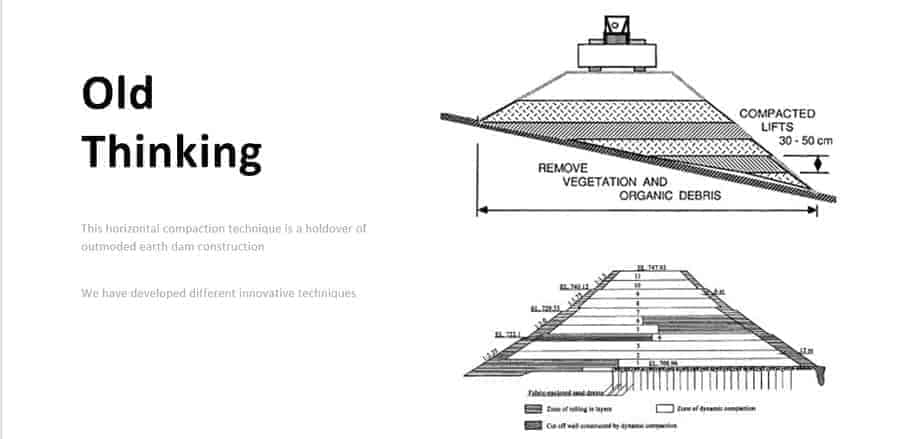

2.Horizontal flat compaction (known as ‘pancake compaction’)

Flat layers of compaction allow the water to exit the dam by travelling laterally through the dam wall interior between the compaction layers – much like honey drips out of pancakes

The horizontal compaction technique is old thinking

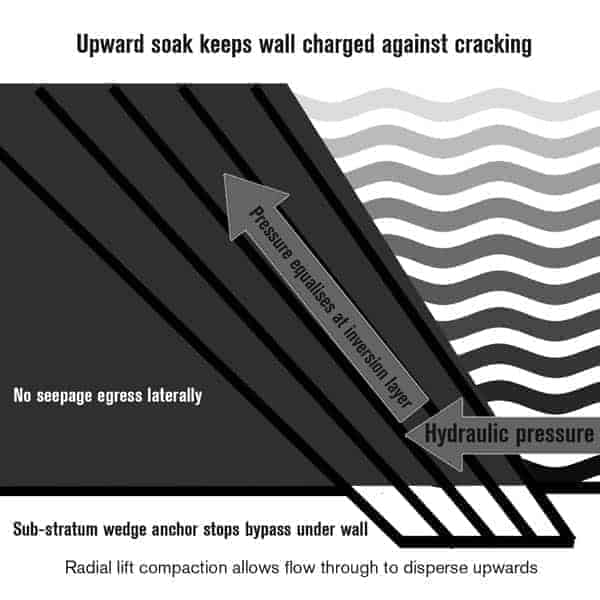

New compaction thinking

Linear radiating lifts with layered Bentonite seams eliminates water loss.

This technique releases hydraulic pressure upwards and disperses it non-destructively due to the angle of repose

The whole wall is anchored with an advanced keying technique using a 22.5 degree inverted sub-stratum bypass lock wedge

The benefits:

- No lateral seepage

- Wall protected against cracking

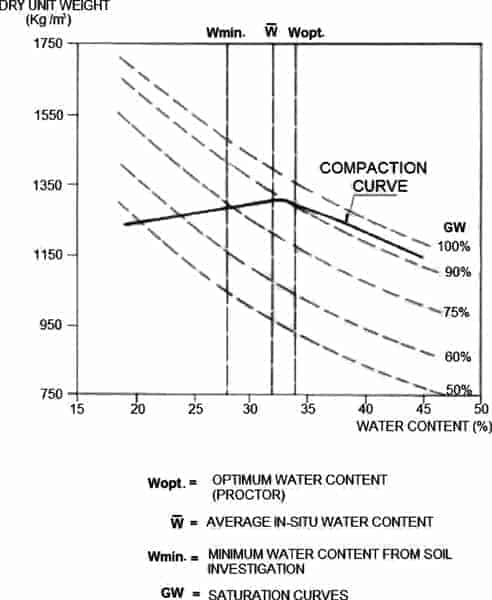

Saturation mechanics

Internal water pressure performance and saturation vs compaction curves in maximum, minimum and optimal diaphragm wall interface water content situations

The impervious core results in a highly heterogeneous wall integrity with impressive transverse and tensile stress capability to stabilize hydrostatic pressure in piping risk zones.

The average pressure of the ‘wetted area’ between wall crest and wall foot is ½ w × h (in kN per unit area) – with the equivalent density of water equalling 10 kN/m³

The end result